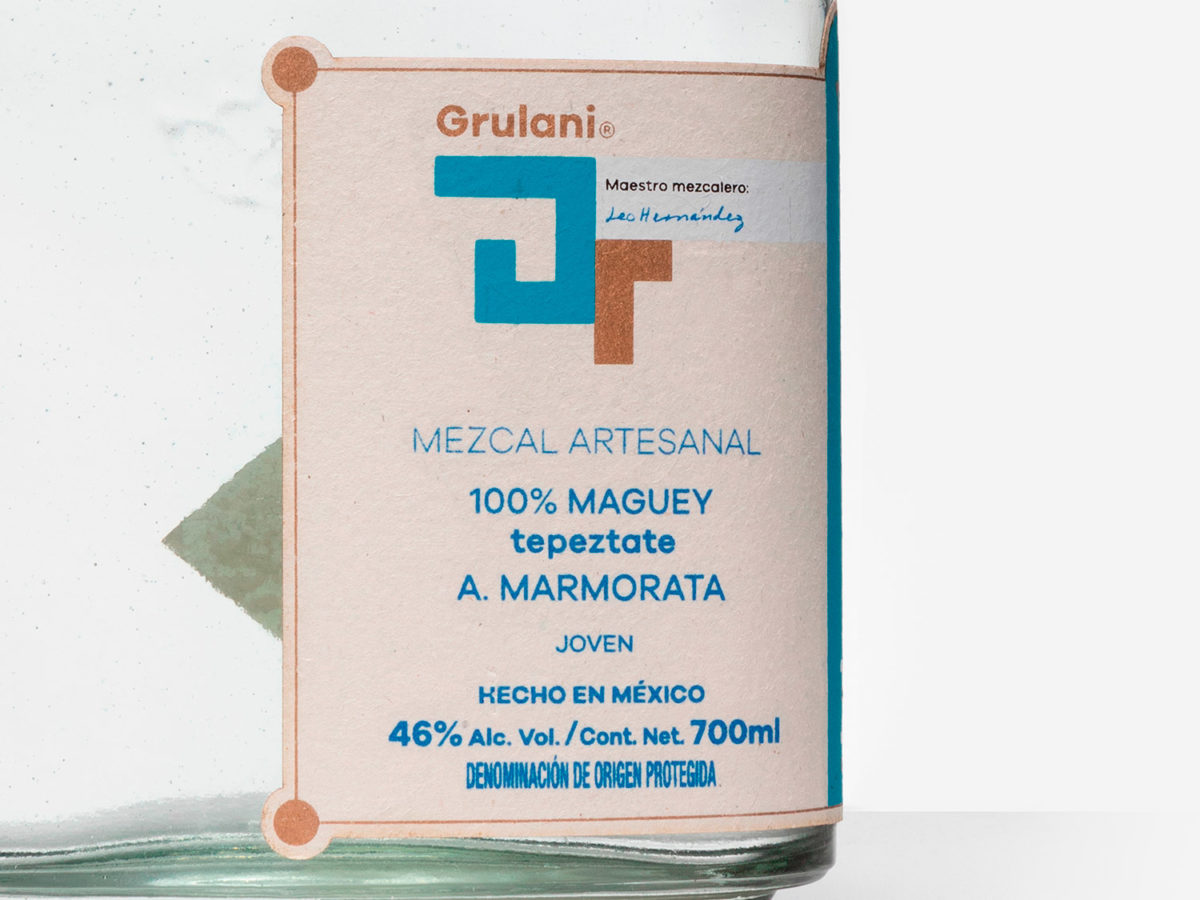

Every detail of the Grulani bottle is a tribute both to the imagery of our Mexican ancestors and to the culture and tradition of mezcal in our land. The result is an elegant presentation that is Mexican as well as universal. Inspired by the epic and ancestral Zapotec art, the bottle’s characteristic curves that shaped our ancestors have been reinterpreted in a singularly designed piece of the highest quality.

A 100% Artisanal Process

Our bottles are molded in the municipality of Tlaquepaque, Jalisco, using the technique of recycled, mold-blown glass. We use the same wood used in our ovens to make the base and top, and the labels are printed on paper made from maguey fiber.

The entire process is completely artisanal. Recycled glass, mainly from soft drink bottles, is introduced into high-load aluminum-filled refractory brick ovens. These furnaces are built in a vault shape and reach a temperature of 1200 degrees. To do this, blocks of clay bricks and ceramic fiber are used, which isolate the furnace from the outside so as not to waste its high caloric power.

This manner of production represents the strong glass blowing tradition of our region

The process of creating the bottles first involves the hornero, who melts the recycled glass, followed by the sacador, whose function is to naturally extract the fused glass in the right quality and quantity to create the shape of our bottle. Once the glass has been extracted, it is inserted into the mold of the Grulani bottle, and the cortador separates the excess molten glass part. With the glass inside the mold, the blower closes the cavity and injects the exact amount of gas to shape and adapt it to the exact volume of the bottle. The pasadores then move the still-glowing glass bottles to the resting area, where the arquero places them one by one, so that they gradually temper to avoid cracking. This last step is critical to creating our bottles: they must rest at 500 degrees for 18 hours.

This complex, completely traditional and artisan way of working represents the strong tradition in our region for blown-glass, and ensures that each bottle of Grulani is a unique and irreplaceable piece.

The Top, Elegance and Protection

The top is a key element in the packaging of mezcal. As a high alcoholic beverage, its preservation and sealing must be perfect, preventing alcohol evaporation and also providing secure transport and use. The type of wood used is essential: A soft or porous wood such as pine would not properly perform its dual function of sealing and protecting.

Ash wood plugs

Ash carved base (premium editions)

Grulani’s bottle tops are manufactured in Tlaquepaque, Jalisco. They are a unique design and are made from white ash wood, ideal for our bottle, without treatments or esthetic additives such as varnish, and are complemented by a synthetic cork, to strictly comply with FDA requirements. Mezcal corks cannot be porous in any way due to the high ABV of the spirit. We use synthetic corks to avoid this issue, and also to avoid the “staining” of mezcal that can occur with the use of a natural cork.

With the same ash wood that we make the tops, we cut the elegant Zapotec base that’s included in Grulani’s premium presentations. It’s a unique pedestal to enhance the beauty of the bottle and its organic and artisan spirit. The base, which remains in constant contact with its surface, symbolizes the permanent connection of each bottle with our ancestral roots, immovable and irreplicable.

Maguey fiber paper labels

The Grulani label is made from 100% organic paper, extracted from bagasse, the pulpy residue left over from the distillation process of our mezcals. We produce the paper in San Agustín Etla, Oaxaca, where the fibers are artisanally treated and processed to create the textured paper. The printing process is also artisanal, using a layered screen-printing technique.